Manufacturing

Innovation and Consistency in Our Manufacturing

We collaborate from concept to completion, tailoring solutions to your needs. Our adaptive manufacturing process combines dedicated lines, lean methods, and skilled teams to ensure efficiency, quality, and flexibility—delivering unique, high-value results that evolve with your project.

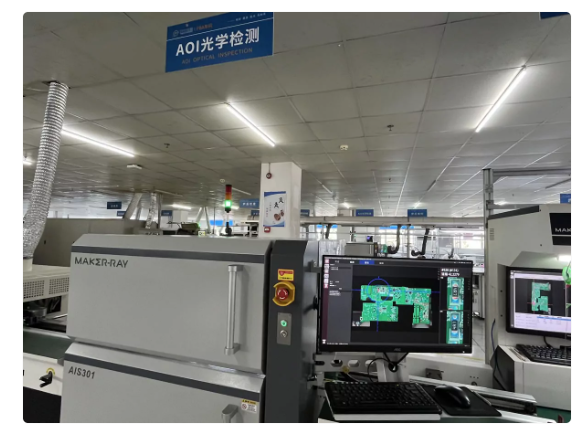

On the line

Precision, monitoring and continuous improvement. Dedicated production lines give on-site support for real-time quality control and swift response. Finished products undergo thorough multi-point inspection before shipment. Our PPM rates routinely beat industry averages thanks to a culture of quality woven into our work

At the source

Components meet our standards before assembly begins. We rigorously vet suppliers and subject incoming parts to visual and functional testing to ensure compliant, sustainable and cost-effective outcomes at all times. Only those meeting specifications move forward to the line. This step ensures integrity of materials at their origin.

After delivery

Warranty analysis and education drive better outcomes. Returned products undergo diagnosis at our laboratory to determine root causes. For issues of misuse, we provide guidance to improve customer experience. For production defects, our first priority is meeting the customer's immediate need. All learnings feedback to enhance quality at its source

✖